Semi-Auto Ubushushu Transfer Screen Umgca woShicilelo

UMTSHINI WOKUSHICILELA NGESkrini

Isihlomelo

1. 1 Uluhlu lwezicelo:

Umatshini we-ZSA-1B ufanelekile ukuprintwa kwephepha, i-PCB, iplastiki, isinyithi, iglasi kunye nemveliso eyenziwe.

1.2.Iimbonakalo:

1.2.1 I-stainless steel worktable, i-intshi yangaphambili-ngasemva kunye ne-right-left, kunye nenkqubo yokushicilela ngokukhawuleza kwaye kulula.

1.2.2 Iindlela ezintathu zokulawula zingakhethwa: manual, single, automatic

1.2.3 Ukuze kuhambelane ne-Varity ye-inki kwaye ufumane i-printing effect eyahlukileyo, i-scraper kunye ne-inki yokubuyisela isilayi inokulawulwa ukuba ime ngasekunene okanye ngasekhohlo.

1.2.4 Ukwamkela izinto zombane ezigqwesileyo ezenziwe ngabavelisi abadumileyo, iimoto kunye nePLC.Isikhokelo somgca esichanekileyo esichanekileyo siqinisekisa ukusebenza okugudileyo kunye nokuqina kwebhilikhi yomatshini.

2. Iinkcukacha

| 1 | Umzekelo | XH-6090 |

| 2 | Indawo yoShicilelo eMax | 600x900mm |

| 3 | Ubungakanani bokusebenza | 700x1000mm |

| 4 | Ubukhulu beSakhelo seSkrini | 1380x1100mm |

| 5 | Ukutyeba | 0-20mm |

| 6 | Isantya esiphezulu.Ushicilelo | 13/min |

| 7 | Uxinzelelo lomoya | 3HP, 5.5-7.7kg/cm2 |

| 8 | Ukunikezwa Amandla | 380V,2KW |

| 8 | Ubungakanani bubonke | 1600mm*1060mm*1680mm |

| 9 | Ubunzima | 580kg (malunga) |

| 10 | Umbala weCase | Mhlophe/Blue |

Sinokwenza ubungakanani obunye kubasebenzisi.Ubungakanani obulungiselelweyo kunye nobunzima be-pls bubambelela kwimveliso yenyani endaweni yoko.

3. IiNkcazo zePhaneli yokuSebenza

- Isalathisi samandla

- Barometer yoshicilelo squeegee

- Ushicilelo Iqhosha lokulawula isantya

- I-oyile yokubuyisela isantya sokulawula iqhosha

- Ubalo loshicilelo

- Ukuprintwa kwesibini

- Imo yokusebenza

- Umboniso wexesha elizenzekelayo

- Ixesha elizenzekelayo

- Inyuka isihla

- Ukubuya kwe-oyile

- Ukuguqulwa kokukrala

- Imowudi yokufunxa umoya

- Ukubuya kweoli ngokukhawuleza

- Ukushicilela

- VULA/Vala i-Off

- Uxinzelelo lweScraper

- Ivalve yokhuseleko

- Intloko yoshicilelo

4. Ufakelo kunye noVavanyo

4.1 Umatshini kufuneka ufakwe kwindawo ecacileyo, kwaye ubushushu bugcinwe kwi-18-28 degree.

4.2 I-fastener yokukhangela ifanelekile, kwaye inxalenye ehambayo ineoli yokuthambisa emva kokuvula ibhokisi yomthi.Khetha indawo yokufakela iqula kumatshini, faka irabha emi-4 emilenzeni, uyilungelelanise kwaye ugcine itafile yokusebenza ngokuthe tye.Ucingo oluphantsi kufuneka luqhagamshelwe kumatshini.

4.3 Ucingo olunombala ophindwe kabini lucingo oluphantsi, olunye lucingo lomlilo.Emva kokuba iingcingo zixhunywe kakuhle.Cinezela 'Imo Yokusebenza' ukuya 'kwiManuwali'.

Cofa u-'Air Suction Mode' 'ukufunxa rhoqo'.

Vula amandla (jonga umfanekiso 1.4).Vula i-'Safety Valve'.

Oko kuya kwenza ukuba ifeni isebenze.Beka i-lager surface paper kwitafile yokusebenza, ukuba iphepha lifunwe yitafile yokusebenza.Kuthetha ukuba uqhagamshelwano lweengcingo luchanekile.Ukuba iphepha livuthelwe ngumoya, oko kuthetha ukuba ucingo lomlilo lwamandla luchasana nesigaba, buyisela umva naziphi na ezimbini zocingo lomlilo.

4.4 Uxinzelelo lomoya kumatshini yi-5.5 ~ 7KG / cm2.Ukuba uxinzelelo lomoya lungaphantsi kwenani, khupha i-adjuster, ujike i-clockwise, yenza uxinzelelo lomoya lunyuke.Ukujika ngokuphambeneyo kuya kwenza uxinzelelo lomoya lube phantsi.

4.5 Cofa u-'Operation Mode' kulawulo 'ngemanuwali'.Vavanya umatshini phezulu naphantsi, intshukumo yasekhohlo nasekunene.

Cofa iqhosha elithi 'Scraping conversion', vavanya i-scraper, kunye ne-oil return scraper.

Isilumkiso: Ayikwazanga ukwenza omnye umsebenzi, de zonke zisebenze kakuhle.Ngaphandle koko, kuya kuwonakalisa umatshini.

4.6 Kugqitywe apha ngasentla , kulandelelwa uvavanyo lwe-Automatic neSingle printing.

4.6.1 Cofa u-'Operation mode' ku-'Single', nyathela i-pedal yonyawo, emva koko ugqibezele ukuprinta kube kanye.

4.6.2 Cofa 'iqhosha lokuBuyisa i-Oli ngokukhawuleza', umboniso wesikrini

Intshukumo yile:

Phantsi-Intshukumo yasekhohlo ye-Scraper--phezulu, i-Scraper intshukumo yasekunene

Inokunyusa ukusebenza koshicilelo.

4.6.3 Cinezela 'Ushicilelo lwesibini' VULA, intshukumo yile:

Ezantsi—Intshukumo yasekhohlo — Ekunene —- Ekhohlo — Ekunene — Phezulu

Ilungele ushicilelo lwe-inki etyebileyo.

4.6.4 Cinezela 'Imo yokusebenza' kwi-Automatic, lungisa uLawulo lweSibali-xesha KT (0~10S).Umatshini wagqiba yonke intshukumo ngokuzenzekelayo.(Ifanele umsebenzi onobuchule, endaweni yoko i-Pedal ye-Foot)

4.6.5 IQhosha likaNgxamiseko

IQhosha likaNgxamiseko linokuphakamisa xa umatshini usebenza.Kufuneka unyathele i-Pedal yoNyawo ukwenza umatshini usebenze emva kokusebenzisa iQhosha likaNgxamiseko.

5. Ukuchaza umsebenzi

5.1.Faka kwaye uhlengahlengise iSakhelo soMnatha

Jikela ku-'Offer Air' (njengomfanekiso1.35), yenza iScraper phezulu, ukhulule isikrufu se-Net Frame Arm screw (njengomfanekiso1.9).Lungisa iArm yeSakhelo soMnatha kumacala omabini ukuya kubude obufanelekileyo (njengomfanekiso2.25), faka isakhelo somnatha kwisibambiso uze uqinise isikrufu.(njengomfanekiso1.29).Igqityiwe ifakiwe, qinisa isikrufu.(njengomfanekiso1.9)

5.2.Lungisa ubungakanani boshicilelo.

Buyisela irabha ye-scraper yokuprinta ukulungisa ububanzi bokushicilela ngokwesicelo sakho.(njengomfanekiso1.33).

Lungisa ubude bokushicilela: Khulula izikrufu ezi-2 (njengomfanekiso1.11), lungisa ekhohlo nasekunene kwindawo efanelekileyo.Qinisa isikrufu.

Ushicilelo kunye nesantya sokubuya kwe-Oyile luhlengahlengiso (njengomfanekiso3) 'Isantya soShicilelo', kwisantya sakho esifanelekileyo.

5.3.Landela ulandelelwano olungezantsi ukulungelelanisa i-scraper kunye nokubuyisela imela yeoli.

a.Ukujikeleza: khulula izikrufu ezi-4 (njengomfanekiso1.24) ukulungisa ukujikeleza.

b.Ukunxulunyaniswa: Lungisa izikrufu ezi-4 (njengomfanekiso1.12) ukugcina i-scraper kunye nokubuyisela imela yeoli ihambelana nomphezulu we-Net Frame.

c.Isantya: Lungisa i-4 screw (njengomfanekiso1.12) ngakwesokudla ukulawula isantya sokuphakamisa i-Scraper kunye ne-oyile yokubuyisela imela.Lungisa 'isantya sokushicilela' ukulawula isantya se-scraper.

d.Uxinzelelo lwe-scraper: Lungisa ivalve yoxinzelelo (njengomfanekiso1.39) ukulawula uxinzelelo lwe-scraper (njengomfanekiso1.38).Funda inombolo evela kwiBarometer.

e.Tsala iqhosha 'lokushicilela intloko' ngaphandle (njengomfanekiso 3.19), ukothula imela yokukrala kunye ne-oyile yokubuyisela.Kufakwe imela yokukrala kunye ne-oyile yokubuyisela cofa 'intloko yokushicilela'.

5.4.Lungisa ubude phakathi kwesakhelo somnatha kunye netafile yokusebenza.(Ngokutsho kobunzima bomsebenzi) Ngasemva komatshini, vula umnyango.

Khulula isikrufu.(jonga ngezantsi ifoto) Jika intonga iye kwicala elichasene newotshi ukuya phezulu, jikisa intonga iye ezantsi.

Qinisa isikrufu.

| HAYI. | Igama | HAYI. | Igama |

| 1 | I-adaptha yokutshintsha i-pedal | 22 | Air Drum for scraper |

| 2 | Ivili elijikelezileyo | 23 | I-Ink Knife Lock Screw |

| 3 | Igalelo lamandla | 24 | I-Ink Knife Rotative adjustor |

| 4 | Ukutshintsha Amandla | 25 | Ingalo yeSakhelo soMnatha |

| 5 | Isilungelelaniso esincinci setafile yokusebenza | 26 | Intsika yeLift Net Frame |

| 6 | I-Worktable Tshixo Screw | 27 | Isilungelelanisi sesantya seLift Net Isakhelo |

| 7 | Isakhelo esiNxulumayo soMlungelelanisi ojikelezayo | 28 | Phakamisa i-Net Frame Air Drum |

| 8 | I-Net Frame Height eLungisiweyo kwiScrew | 29 | Screw ukuQinisa isakhelo somnatha |

| 9 | Isakhelo somnatha eKhohlo&Ekunene siLungiselelwe isikruru | 30 | Ekhohlo & Ekunene isakhelo somnatha |

| 10 | Imoto | 31 | Itafile yomsebenzi |

| 11 | Isitshixa sokushukuma | 32 | Hook ye-Ink Knife |

| 12 | Scraper Speed Adjuster | 33 | Scraper |

| 13 | 34 | Imela ye-Ink | |

| 14 | Air Drum for scraper | 35 | Air Drum for scraper |

| 15 | 36 | Ukuyeka ngokuNgxamisekileyo | |

| 16 | Tsala iChain | 37 | Iphaneli |

| 17 | 38 | I-Scraper Barometer | |

| 18 | Umthunzi Wangaphandle | 39 | Scraper Pressure Adjustor |

| 19 | 40 | Umnyango weBhokisi yoMbane | |

| 20 | I-Ink Return Knife Pressure Adjustor | 41 | I-Pedal yeenyawo |

| 21 | Scraper Pressure Adjustor |

6. Ugcino:

6.1.Kuphephe i-inki kunye ne-organic solvent evalela umngxuma wokufunxa kwitafile yokusebenza.

6.2.Lahla i-oyile ye-injini encinci 10 # kwintsika nganye yokutshintsha okusebenzayo.

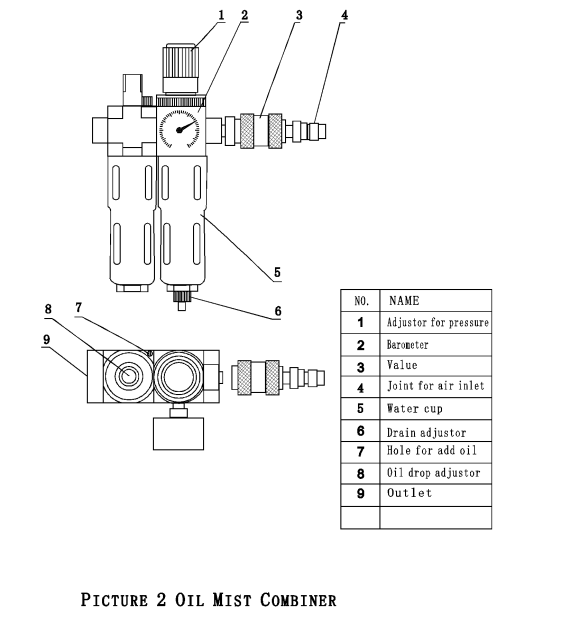

6.3.Umtshini une-oyile edibanisa inkungu (jonga umfanekiso wesi-2).

6.4.Coca isihluzo (njengomfanekiso2.7).Nikeza umoya, vula i-drain knob (njengomfanekiso2.8).

Hlamba isipontshi kwikomityi yamanzi (njengomfanekiso 2.7) rhoqo.Susa isihluzo, khupha isipontshi, usishiye imizuzu embalwa emanzini acacileyo, kwaye uyomise.

7. Isiqhoboshelo

1. Incwadana yokusebenza

2. Screwdriver 2 pcs, i-10' Spanner, i-hex Spanner, iRob

3. 4 Unyawo lwerabha

4. Scraper kunye Ink yokubuyisela imela 350, 400

********************************************** ********************************************** ********************************************** ******************

UMTSHINI WEPOWDER COATING

Inkcazo emfutshane

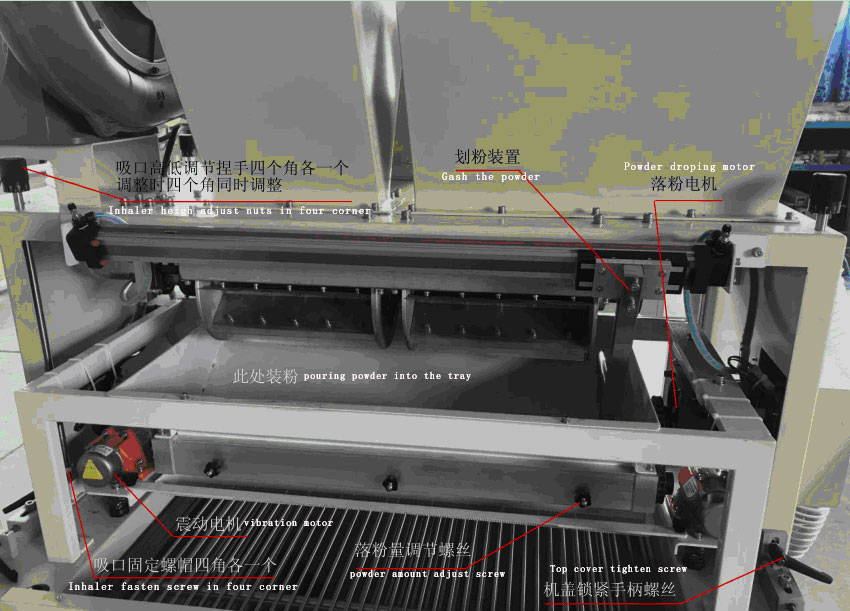

Emva kokushicilela izixhobo ezihambelanayo ezithatha indawo yezandla zemveli.Lo matshini ulungele ukusetyenzwa, usebenza kakhulu, uguquguquka, kwaye awunangcoliseko, nto leyo eyandisa imveliso kunye nokusetyenziswa kwezinto ezikrwada, kunye nokuvelisa imifanekiso emihle.

Kulo matshini, iinxalenye zesikhundla esiphambili ezifana ne-powder sucking, i-transducer ithunyelwa ngaphandle kunye neenzuzo zokuqina kunye nokuzinza.Ngokukodwa, lo matshini usebenza kakuhle kunye nabo banemfuno ephezulu yephepha, ifilimu, i-glitter, kunye nomgubo onyibilikayo oshushu.Zonke iidrive kulo matshini aziguquki ngesantya esingenasiphelo.Ukuba iyafuneka, inokunxibelelana nezixhobo zokomisa kunye nezixhobo zokunyanga ifoto ye-UV.

IiParameters ezingundoqo zobuGcisa:

| Umzekelo | Amandla Aphelele | Ububanzi bebhanti yoThumelo | Ububanzi bePowdering | Ukutyeba kwePhepha | Imilinganiselo iyonke | Isantya (IiPC/Iyure) |

| ZSCT-II | 4.5KW | 1000(mm) | 900(mm) | 1—5(mm) | 2000*1700*2000 | 2000 |

Funda incwadi ngononophelo, phambi kokuba usebenzise umatshini.Musa ukulungisa naliphi na iqhosha phambi kokuba uqhagamshele kumandla ombane.

Incwadi yoMsebenzi

Isikhumbuzo esifudumeleyo: Ipowder ayiyi kusasaza de ifilimu idluleisivamvo.

Lo matshini uxhotyiswe ngokutshintsha okwahlukileyo kuzo zombini amandla ukufunxa ukuya phezulu nasezantsi, kunye nokutshintsha ukuhambisa, uthuli, ukondla umgubo, kunye ne-electrostatic neutralizer.

Inkqubo yokuqalisa

- Vula amandla aphambili kwicala lasekhohlo.

- Vula iswitshi yamandla (Jonga umfanekiso II-2).

- Ukutshintshela phezulu kwimoto yokufunxa amandla (Jonga umfanekiso II-8), kwaye ulungele ukuphindaphinda kwe-transducer ukuya kwi-38-42HZ.

- Ukutshintshela ezantsi amandla okufunxa imotor (Jonga umfanekiso II-11), kwaye ulungele ukuphindaphinda kwe-transducer ukuya ku-55-65HZ.

- Tshintsha amandla okuhambisa (Jonga umfanekiso we-II-4), kwaye ulungise ukutshintshela kwi-20-65HZ.

- Tshintshela kwi-adjuster yokutya yomgubo (Jonga umfanekiso we-II-15), kwaye ulungise ukutshintshela kwi-20-65HZ.

- Galela umgubo onyibilikayo oshushu kwitreyi yothuli, kwaye emva koko utshintshe i-motor yothuli (Jonga umfanekiso II-17).Okokuqala, ukulungelelanisa isantya sothuli (ukukhawuleza, umgubo ngakumbi).Okanye ukulungisa amantongomane amathathu phantsi kwefunnel yothuli (Jonga umfanekiso we-I-4) ukuthethelela ubungakanani bepowder, ukwenzela ukuba kuhlangatyezwane nemfuno yemveliso yobunzima bomgubo kunye nokulinganisela.

- Umqokeleli wepowder kwicala lasekhohlo (Jonga umfanekiso we-II-21) unomsebenzi wokukhuthaza i-powder-cycling.Ngokwesiqhelo, uluhlu lutshintshwa ukusuka kuma-60 ukuya kuma-70.

- Vula iswitshi ye-electrostatic neutralizer (Jonga umfanekiso II-13)

Lungisa umatshini

1.Ukulungelelanisa isithuba phakathi kokufunxa umgubo ukuya phezulu nasezantsi ukuya kwi-2–3mm.

Ukuba kusekho ivili legiya kwisampulu ngelixa isebenza (ngesiqhelo, sele ihlengahlengiswe phambi kokukhutshwa), ungalungisa umphakamo wokufunxa amandla ukuya phezulu ukuhlangabezana neemfuno zemveliso.

1.1 Khupha amandongomane amane ekoneni.Isikhumbuzo: Lungisa ubude kuphela emva kokukhulula amandongomane amane.(Jonga umfanekiso)

1.2 Khulula inati (Jonga umfanekiso 1), lungisa umphakamo ukuze ufunxe amandla ukuya phezulu (Jonga 1, 21, 22).Okanye (Jonga umfanekiso 1) Jika isithuba sisondele ngasekunene.Jika ngokuchasene newotshi umsantsa ube banzi.

1.3 Jika amantongomane ngokucokisekileyo kwindawo yokufunxa umgubo, yenze ibhalansi.(Jonga umfanekiso 1) Qinisa izikrufu ezimnyama (Jonga umfanekiso 1)

Inkqubo yokwenziwa ngokutsha komgubo

1.Ukuba kukho intsalela yomgubo kwimveliso, kungcono ukonyusa isantya somgubo ukufunxa imotor ukuya phezulu (Jonga umfanekiso Ⅱ-8).Nangona kunjalo, ukuhamba komoya okuphezulu kunokubangela ukugcwala kwephepha, ukulungelelanisa kakuhle.

Ukuba kusekho intsalela yomgubo kwimveliso, emva kokunyusa isantya sokufunxa umgubo ukuya phezulu, jonga umphakamo wokunyuka nokuhla.Ukuba i-gap ibanzi kakhulu, landela inyathelo langaphambili ukulungisa ubude.

Qwalasela isingxobo sothuli ngaphandle komgubo ukuvala umngxuma womoya.Ngokobunzima bepowder, kuyimfuneko ukucoca isikhwama sothuli ukuphepha ukuvala umngxuma womoya.

Jonga icala elisezantsi lomatshini, qinisekisa ukuba inkqubo yokuncedisa umgubo iyasebenza.

Ukulawulwa kobungakanani bomgubo wokuxubha

- Lungisa isilawuli sesantya sokushukuma umgubo (Jonga umfanekiso II-22).

2. Lungisa isilawuli sesantya sokushukumisa umgubo (Jonga umfanekiso II‐22) awukafikeleli kwimfuno yakho.Inokulungelelanisa isikrufu ngasekhohlo kwekheji (Jonga umfanekiso).

Inkqubo yokucima kombane

- cima umlawuli wetreyi yothuli (jonga umfanekiso II -17)

- Vala isilawuli sokungcangcazela (jonga umfanekiso Ⅱ-22)

- cima isitshixo samandla ukufunxa phezulu (jonga umfanekiso II-7)

- cima isitshixo samandla okufunxa ezantsi (jonga umfanekiso II-10)

- vala utshintshe unikezelo (jonga umfanekiso II-4)

- Ukutshintsha kokutshintsha kwe (jonga umfanekiso II-21)

- utshintsho lomlawuli wokuhanjiswa komgubo (jonga umfanekiso Ⅱ-15)

- cima isitshixo samandla amakhulu (jonga umfanekiso II-2)

- Coca iphaneli yokulawula kwaye uyigubungele ngejacket yothuli

Ukuya koomatshini

1. Emva kokusebenza ixesha elithile, vula i-baffle, kwaye ugcwalise ezo ndawo zisebenzayo nge-20 # yeoli ye-injini.Ukuba ityathanga lithambile, sebenzisa i-elastic gear ukulungisa.

2. Ngelixa utshintsha izinto eziluhlaza ezifana ne-glitter kunye ne-hot melting powder, sebenzisa umoya oxinyiweyo ukucoca zonke ezi ndawo ukuze ugweme umgubo oxutywe.

3. Ngokutsho kobunzima bepowder, kuyimfuneko ukucoca isikhwama sothuli ukuphepha ukuvala umngxuma womoya.

Ukusebenza umatshini ongenanto

Vula iswitshi ukwenzela ukunyuka komatshini (Jonga umfanekiso wesi-3).Vula iswitshi kwisiqingatha esiphezulu somatshini uya kuphakama, kungenjalo yihla.

Guqula ukuhanjiswa kweswitshi ngokuzenzekelayo (Jonga umfanekiso we-II-4), kwaye uvale yonke enye iswitshi, yenza ifilimu yokufudumeza kwangaphambili idlule.

Isicombululo sempazamo

1. Nceda ubuyisele irhuluneli yesantya ngelixa ingasebenzi.

2. Nceda ulandele umyalelo wokuhamba koMatshini ukuba umgubo awufunxanga ngokupheleleyo njengangaphambili.Okanye unokwandisa i-destaticizer ukujongana nale ngxaki.

3. Nceda ujonge umgubo ukuba ucocekile kwaye womile ukuba uthuli ngobunzima.Ukuba umgubo umanzi, nceda uwafake phantsi kwelanga.

4.Ukuba ibhloko yetyhubhu yokugaywa ngokutsha kwepowder, Nceda ujonge ezantsi kwesakhelo uvule inkqubo yomncedisi wentsalela.Okanye Jonga umgubo ufunxa ezantsi, qinisekisa ukuba uyasebenza.

5.Vula iswitshi kwisiqingatha esiphezulu somatshini uya kuphakama.

********************************************** ********************************************** ********************************************** ******************

I-Manipulator